In 1937, when Taiichi Ohno worked at Toyoda Spinning and Weaving heard a man say that the production of an American worker was nine times higher than a Japanese. When in 1945, Kiichiro Toyoda said: "We will catch up with the United States in three years. Otherwise, the auto industry in Japan will not survive”. Ohno thought: "Is it possible that an American could actually exert nine times more physically?". It was clear that the Japanese were wasting something. If the waste was eliminated, the production would increase instantly and this marked the beginning of the current Toyota Production System. Taiichi Ohno categorized the wastes in: overproduction, waiting, transportation, over processing, inventory, motion, and defective products. He was certain that the complete elimination of these wastes would increase the efficiency of the operation. To start Toyota should produce only the necessary, eliminating extra work force.

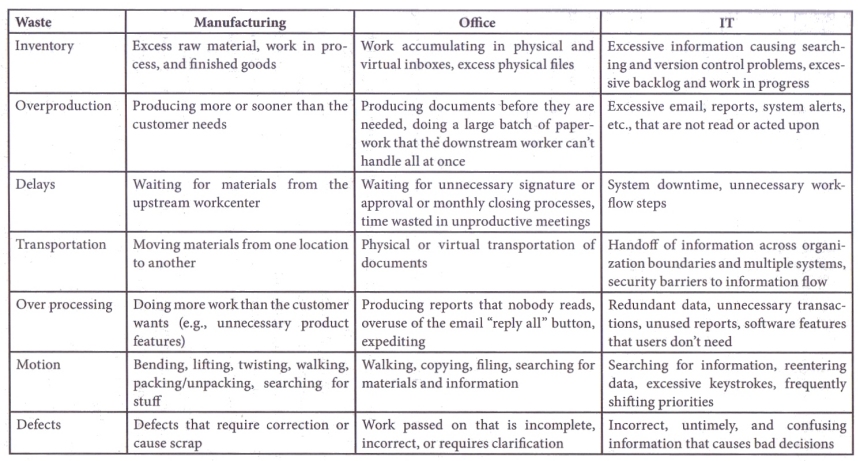

When we talk about waste in IT it is always difficult to identify them clearly. Steven Bell, in his book Lean IT, adapted the seven wastes to information technology also comparing them to the manufacturing and office, as shown in Figure 1. At the end of his book it was possible to find more specific examples that can help in clarifying this concept.

Figure 1. Comparing waste in manufacturing, office and IT. Source: Bell, C. S. and Orzen, A. M. (2011), Lean IT - Enabling and Sustaining Your Lean Transformation (p. 57). New York: CRC Press.

Steven also describes Lean IT assuming two dimensions: the outward-facing aspect to improve management and business processes, and inward-facing using principles and tools to improve operations, services and software development. It is important to clarify this separation in order to understand in which area of IT the wastes are occurring. In Table 1, I present some examples of waste, categorized by inward and outward.

| Inventory | In: Excess specifications caused by slow development (Backlog). Various functions with the same usefulness within the source code or not are used by the system. |

| Out: The number of software licenses is greater than the number of users. Unnecessary duplicate information in the database. Too many links in a system menu that are accessed only by people from other departments. |

| Overproduction | In: Develop something that the client will not use. Rewrite functions that are already done for a project. |

| Out: System releases reports with information that are not used by users. |

| Waiting | In: Development stopped waiting for User Story or any other type of specification. |

| Out: System takes a long time to move from one screen to another, forcing the user to wait. |

| Transportation | In: A programmer specifies what is developing and sends to the responsible (Product Owner). |

| Out: Making unnecessary integrations with other systems (eg, Web Services). |

| Over processing | In: Develop code without optimization, causing overprocessing of the machine. Unproductive meetings (may be outward-facing too). |

| Out: Accumulating many features in one system screen, leading to overprocessing. |

| Motion | In: Accessing help, search on Google or any other site to answer simple questions of programming. |

| Out: User searches for information in other system screens and then back to where it was. |

| Defects | In: : Inconsistency between the specification and the expected result. |

| Out: System presents a programming error during the user experience. |

Table 1. Examples of waste in Lean IT categorized by in and out dimensions.

The worst waste in IT, manufacturing or office is overproduction, because with it comes all the others. Understanding each one of the waste and getting focused on reducing, starting with overproduction which, is the first step towards people's awareness and the evolution of organization. This was how Taiichi Ohno began the Toyota Production System.

The conclusion is: There's no need for revolutionary systems of software or management to help a business, but first understand what should be reduced and work without losing focus, after that, it would bring rapid results. For example, imagine a factory that saving two seconds during the production of one piece. Assuming that production is 200,000 pieces per month, the company would save 111.11 hours of energy expenditure on machines, manpower, etc. We understand that after eliminating waste, the cost decreases automatically. The same situation could be applied to an IT company if we take into consideration the amount of time wasted day after day with unproductive meetings, phone calls, emails, etc. Adding the time spent by all employees, considering a month's work, we'd get a very high number. In other words, the waste should be eliminated and understood by organizations.

Bibliography

- Ohno, T. (1997), The Toyota Production System by Taiichi Ohno. Portuguese Version - Porto Alegre: bookman

- Bell, C. S., Orzen, A. M. (2013), Lean IT - Enabling and Sustaining Your Lean Transformation. New York: CRC Press