The kanban ("visual card") is the method of operation of the Toyota Production System. It has been used since 1953 and its inventor Taiichi Ohno, describes it as: an autonomic nerve in the production line. With it the workers can work by themselves and make their own decisions. Kanban is usually represented by a piece of paper in a rectangular envelope plastic. The information contained within it may be divided into three categories: collection, transfer and production. The functions of the Kanban are basically:

1) Provide information on pick up and transport

2) Provide information on the production

3) Prevent overproduction and excessive transportation

4) Serve as a manufacturing order and must be attached to the product

5) Prevent defective products

6) Reveal problems and control inventory

Figure 1 shows an example of kanban used by Toyota.

Figure 1. Example of Kanban used by Toyota. Source: Ohno, T. (1997), The Toyota Production System (p. 46). Porto Alegre: Bookman (Adapted from portuguese version).

Figure 2 illustrates a clear explanation of its operation in the production of vehicles. When car number 20 enters the assembly line, a worker fastens a production order (kanban) indicating what type of vehicle it is. When the vehicle crosses the line, other Kanbans are generated and sent in advance for the sub process E, D, C, B and A. The components of the resulting sub-processes are assembled in sequence, fitting itself respectively on the production of the that vehicle in question requested at the right time (neither before not to generate stock or later to avoid interrupting the flow of production). We conclude that the Kanban aims to support the Just-in-time (doing only the required when necessary).

Figure 2. Simple example of using the Kanban method. Source: Ohno, T. (1997), The Toyota Production System (p. 67). Porto Alegre: Bookman (Adapted from portuguese version).

According to Taiichi Ohno, over 200,000 vehicles leaves the Toyota production line monthly. If we consider the type of bodywork, painting, transmission, engine, etc., we could conclude that seldom do we see identical cars. An interesting thing is that Toyota does not receive only one request for production, but many requests coming in every day at the same time. It must plan before producing and for that, Toyota uses Heijunka, Japanese term which means "programming level". An example from Ohno's book - "The Toyota Production System" provides a basic explanation of the term: let's imagine the production of 10,000 cars working 20 days a month. Suppose it is divided into 5000 sedans, 2500 hardtops and 2,500 vans - that means 250 sedans, 125 hardtops and 125 vans are made daily. In the production line they go as follows: one sedan, one hardtop, after one sedan, one van and so on. Thus, the size of the lot and the fluctuation can be minimized in order to have the best result in the Just-In-Time production. When Taiichi Ohno describes the Kanban as an autonomic nerve, he wants to emphasize the importance of this method in the company to respond quickly to market expectations without having to "think". It is therefore concluded that the higher the enterprise is, the better the "reflexes" it needs to have to ensure their survival.

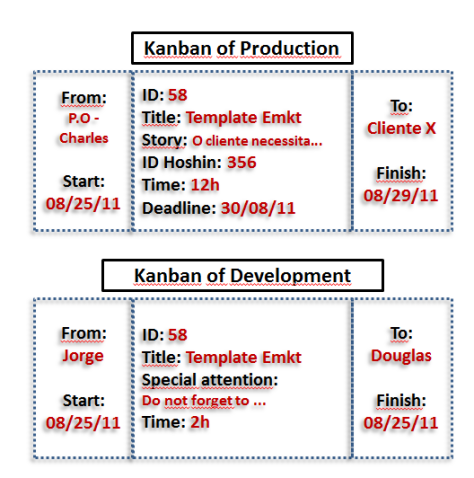

But, how to adapt the use of the Kanban to Lean IT? As you may already know, the IT Kanban method was first adopted by David J. Andersone which must be adapted to the reality of each company. For example, the first columns initially were "to do", "doing" and "done" can be changed to "in progress", "tested", "accepted", "blocking" and so on according to the needs of users of the organization. There are good articles on the subject written by Hiranabe Kenji ("Kanban Applied to Software Development from Agile to Lean" and "Visualizing Agile Projects using Kanban Boards"), as well as examples in Chapter 5 of the book by Steven Bell (Lean IT Enabling and Sustaining your Lean Transformation). I would like to highlight in this article, not a method for its use, but an example with some adjustments in IT, without losing the principles, from Heijunka phase to the distribution of the activities for developers. We'll divide the kanban cards into two types: production and development. Each kanban must have synthesized instructions of what needs to be done, who is coming and for who it should be sent, along with other features that can be added as needed. Figure 3 illustrates some possible features that can be used in the Kanban card production and development.

Figure 3. Characteristics that can be used in a Kanban of production and a Kanban of development.

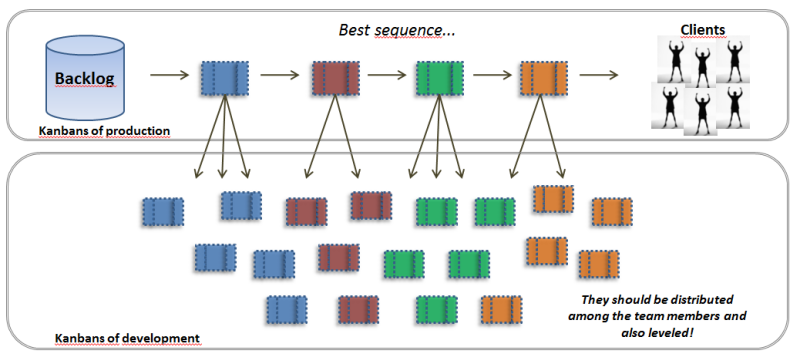

When a market requirement is identified by the organization the first step is to level this requirement through the backlog that a team or company has. The Heijunka should be done taking into consideration the Hoshin of the company and customer expectation. Thus, the workers will be developing the correct task according to "rules" set by high management and the Product Owners (PO - responsible for the projects - voice of the customer within the company). Figure 4 shows an example of the best sequence of activities, after leveling, originated by Backlog (in accordance with the customer and the company's Hoshin).

Figure 4. Best sequence of activities represented by cards Kanban production.

We must understand that in accordance with the requirement described on a card (kanban production) several activities can be represented by other cards (kanban development) and distributed to one or more employees. Suppose that we need to develop an email marketing template identified by a kanban card. The task will be involved by describing simply: PO responsible for approving and delivering, a Web Designer to create the images and layout of elements in email, a copywriter to write the text and an html maker to develop and prepare to send. The second half of Figure 4 shows the development of Kanban and as you may have noted they are not leveled. When we talk about leveling means each employee developing the job at the right time, for example, the programmer only creates the HTML code after all the images and layout elements are completed by Web Designer, before that, he will be working on other activities. When you finish a task must follow the orders of Kanban and send the result to the next reviewer described on the card. I will not explain how to organize Kanban development, because it would mean writing a method which should take into consideration the amount of resources, their characteristics and the time available of the company employees. As described earlier, there are several good articles related to this topic which should be adapted to the reality of each organization.

The applications of Kanban in IT arise due to the desire of companies to improve their development processes. During the applications one must be careful not to lose any of the principles of this powerful method. If used incorrectly it could leave the Kanban development without agility, because the team will spend considerable time searching and trying to figure out what to do with each of the cards, generating waste. In addition, the organization should use it only after Heijunka, otherwise there will be no certainty that it will be developing the correct activity at the right moment, in relation to other tasks. The Kanban method of operation is very effective because with it the Toyota controls the car assembly of an average of over 9000 items each. Before using Kanban it is our job to understand exactly what to do with it.

Bibliography